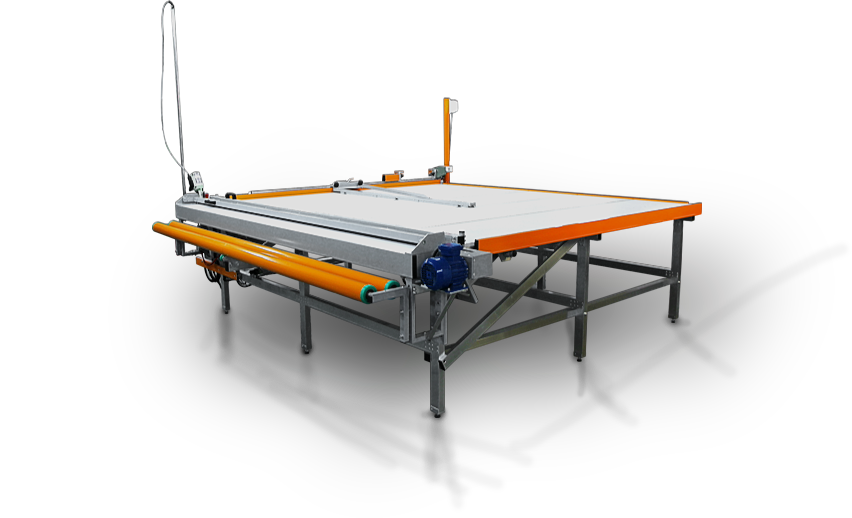

Type-1

Perfect for beginning

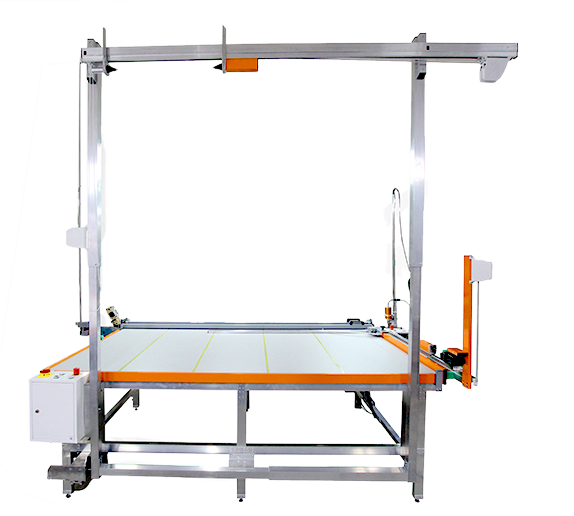

Rollcutter TYPE-1 is recommended to small individual production. It allows you to perform a full production cycle of roller blinds – setting sizes, fabric cutting, attaching the upper tube and mounting the lower bar. Thanks to a completely charge-free training in roller production, easy handling, and low price, the Type-1 is a perfect solution for companies which are starting production.

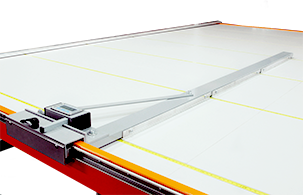

Fast dimension

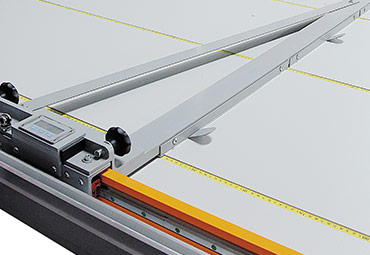

First, you unwind the fabric on the receiving rollers and then precisely set the dimension using Measuring angle bar with digital screen or measures recessed in the table top. Our machine can be equipped in autocentering, which sets the fabrics exactly at right angle to the edge.

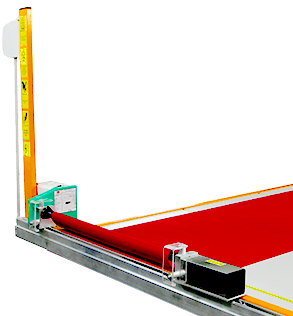

Manual cutting

Fabric cutting on type-1 Rollcutter is performed manually. Firstly the clamp is to be lowered, then the roller knife that is fixed to the guide-bar is to be started and led through the entire length of the fabric.

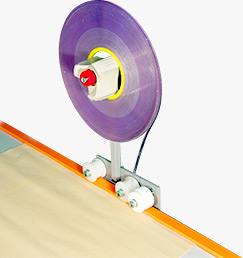

Clever corners

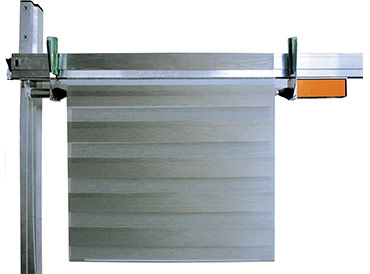

During mounting the top tube to the fabric, you can easily adjust the bumper in the corner to the needed system. You can also install rolling machine, which rolls up the blind 8 times faster comparing to manual. Secondly, Clever Corner is used to quickly stick the rigid tape to the fabric, where you slide the bottom bar. Installation of Tape Feeder will definitely help you with sticking correctly tape and accelerate the process in the same time.

Full quality control

You control quality of production from the beginning to the end. After unwinding the textile, the backlight allows you to check the quality of fabric and eliminate mistakes. Whereas, Control Lift allows you to check the correctness of rolling when the blind is ready.

Additional benefits

Always straight blinds

The Rollcuter has an aluminium construction that allows for precise adjustment of the right angle (diagonal adjustment), clamp adjustment and table levelling, making roller blinds always straight and equal.

Always safe to work with

Each Rollcuter model is built with usage safety in mind. The machines are equipped in sensors that detect objects under the open clamp, emergency safety switches as well as anti-collision systems for the clamp.

Free training

The Rollcutter stands not only for a roller blind producing machine, but also for a comprehensive knowledge on the complete production process. We will train both you and your employees free of charge in order to use the production potential in an optimal way and minimize the time needed to implement changes.

Immediate support

Should you require assistance we will support you as soon as you contact our consultant.

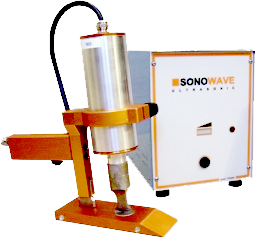

Recommended additional equipment

Technical data

|

Power supply voltage |

Control voltage |

Power supply |

Pneumatic system pressure |

Weight of the 300x300cm |

Construction |

|---|---|---|---|---|---|

| 1~230 V/50 Hz+PE | 24 V /DC | 200 W | --- | 250 kg |

Riveted and screwed, aluminium, EKO |

|

Cutting cycle |

Manual |

|

Knife movement |

Manual |

|

Guide |

Sliding guide with clearance regulation |

|

Knife blade |

Electric circular |

|

Fabric clamp |

Manual-gravitational supported by a self-closer |

|

Cutting width |

up to 3500 mm (price depending on size) |

|

Delivery board length |

up to 3500 mm (price depending on size) |

|

Safety switch |

Manual |

|

Fabric clamp |

One-side |