Model comparison

Cutbooster Manual |

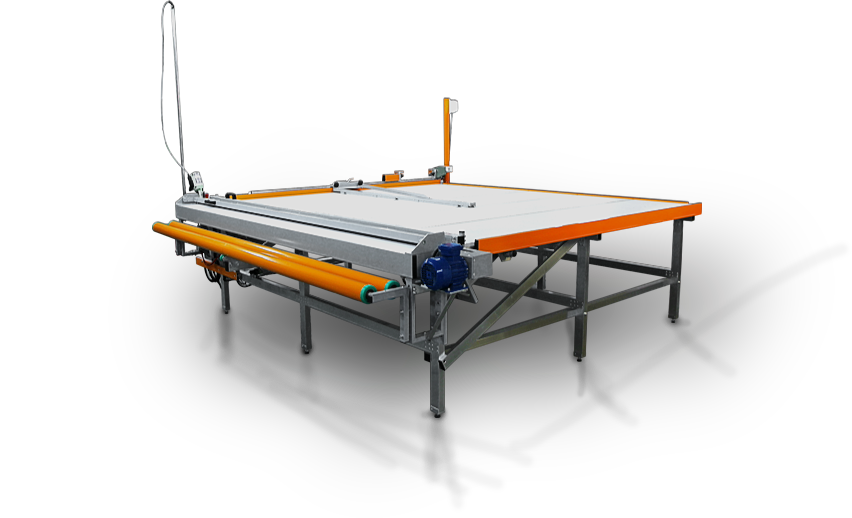

Cutbooster PA-1 |

Cutbooster PA-2 |

Cutbooster PA-3 |

|---|---|---|---|

|

|

|

|

|

Conclusion

| A cutting station equipped with a manual gauge. | A cutting station equipped with an automatic gauge. All you need to do is enter the dimension and the fender instantaneously moves to the preset distance. | The first step toward automation of production. The PA-2 automatically feeds and cuts the material in the preset number of cuts. | A fully automatic cutting line. The PA-3 collects, cuts, and puts away materials automatically. |

| More | More | More | More |

Dimensions set with the precision of 0.25 mm

| Manual, readout of the dimension from a ruler | Automatic after the dimension is entered | Automatic after the dimension is entered | Automatic after the dimension is entered |

Feeding of cut elements

| Manual | Manual | Automatic, 0.4 m/s | Automatic, 0.4 m/s |

Cutting device

| Suitable for any saw used by the customer | Suitable for any saw used by the customer | Automatic, a 400 mm saw with pneumatic pressure, integrated with the cutting cycle | Automatic, a 400 mm saw with pneumatic pressure, integrated with the cutting cycle |

Taking and collection of material

| Manual | Manual | Manual | Automatic |

Cut elements

| depending on the saw used | depending on the saw used | Aluminum | Aluminum |

Fender stroke

| Standard 300 cm | Standard 300 cm | Standard 300 cm | Standard 600 cm |

| Any, as requested | Any, as requested | Any, as requested | Any, as requested |

Fender movement speed

|

Manual movement |

0,9 m/s |

0,9 m/s |

- |

Software

|

- |

Possibility to enter constant dimension corrections for many systems | Possibility to enter constant dimension corrections for many systems | Possibility to enter constant dimension corrections for many systems |

|

- |

A list containing the following columns: dimension and quantity | A list containing the following columns: dimension and quantity | A list containing the following columns: dimension and quantity |

|

- |

Saving completed cuts in a memory | Saving completed cuts in a memory | Saving completed cuts in a memory |

|

- |

Self-diagnostics on the touch panel | Self-diagnostics on the touch panel | Self-diagnostics on the touch panel |

Safety

| - | A manual safety switch | A manual safety switch | A manual safety switch |

| - | - | Saw operation block when the guard is open | Saw operation block when the guard is open |

Supply power

|

- |

500W | 2000W | 7700W |

Guide

4-row, ball, playless, lubricated after a distance of 1,000 km

Design

Riveted-screwed, aluminum

Additional options

| - | Entering the dimension using a USB flash drive | Entering the dimension using a USB flash drive | Entering the dimension using a USB flash drive |

| - | Sending orders from ERP systems or files prepared earlier | Sending orders from ERP systems or files prepared earlier | Sending orders from ERP systems or files prepared earlier |

| - | Connecting a printer or a bar code reader | Connecting a printer or a bar code reader | Connecting a printer or a bar code reader |

| - | Cutlogic - waste reduction software | Cutlogic - waste reduction software | Cutlogic - waste reduction software |

| - | Extended cutting lists | Extended cutting lists | Extended cutting lists |

| - | Change of the dimensions of the station | Change of the dimensions of the station | Change of the dimensions of the station |

| Customization | Customization | Customization | Customization |

| Cutting other materials (steel, wood, PVC) | Cutting other materials (steel, wood, PVC) | Cutting other materials (steel, wood, PVC) | Cutting other materials (steel, wood, PVC) |