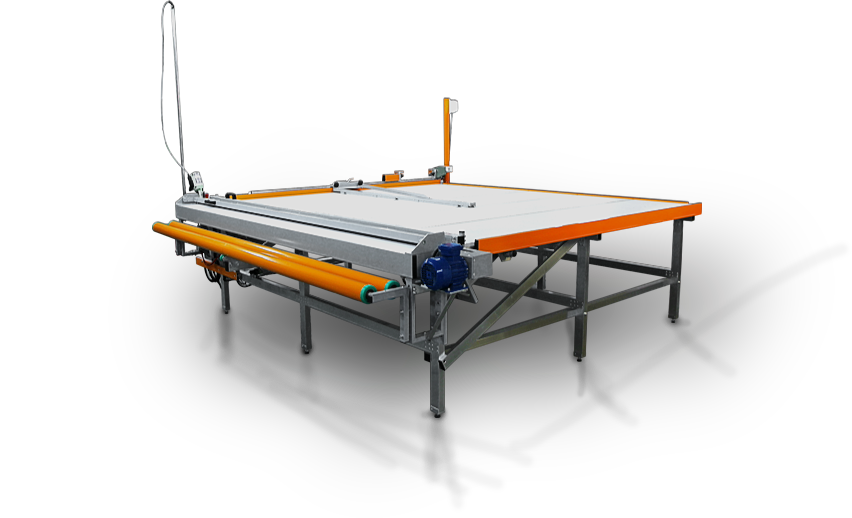

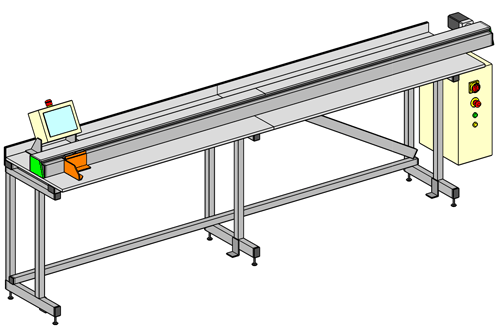

Cutbooster PA-1

Set dimensions in 3 seconds

The cutting stand with an automatic positioning device allows you to quickly adjust the length of the material to be cut. Just enter the dimension on the touch screen and the bumper will immediately adjust to the given distance with a 0,25 mm accuracy

Fits every type of cutting saw

The cutting stand works with aluminium, steel or PVC cutting saws. The automatic positioning device can be mounted to any given cutting machine, while the dimensions and the machine components can be freely determined at the order placement stage. If you already have a cutting stand we can prepare a tailored gauge for it.

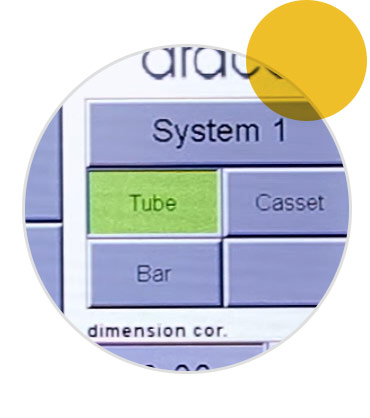

Correction system

If you want to cut sets with pre-defined dimension differences, e.g. pipe, box, or a panel, you can speed up the workflow by using the correction system and immediately changing the bumper settings with one button, along a pre-defined pattern.

Data transfer

The Draco Connect system allows for the orders to be sent directly from the ERP system or a pre-defined file to the machine with WiFi or USB. There is no need to remember the number of cuts, the required length or to change the material - the system will collect the order and will coordinate its implementation.

Check Cutbooster PA-1 in action

Improved work organisation

Code reader

Label printer

The work on the cutting stand can be enhanced even further by using a code reader and a label printer. A code reader allows you to instantly scan a given dimension from a list, while with a label printer each element that has been cut can be instantly labeled and described.

Why Cutbooster PA-1?

- Automatic setting of the fender using a touch panel

- Manual sliding of the material to be cut

- Adaptation to any saw

- A table with a top (standard) or with rollers (option)

- Machine dimension as required by the customer

- A correction system

- Label printer and bar code reader (option)

- Connection to ERP systems (option)

- A servomotor - positioning accuracy +/- 0.25 mm per 3 m

- A playless ball guide (HIWIN)

- CutLogic - cutting optimization (optional)

Customers about Draco

Technical data

- Setting the dimensions

- Automatic

- Feeding of cut elements

- Manual

- Entering the dimensions

- Manual using a touch panel

- Guide

- 4-row, ball, playless, lubricated after a distance of 1,000 km

- Fender stroke

- 300 cm

- Receiving table

- A 300x60 cm table with a top

- Feed speed

- 0.9 m/s

- Precision

- +/- 0.25 mm

- Corrections of dimensions

- Possibility to enter constant dimension corrections for many systems

- Cutting history

- Saving completed cuts in a memory

- Drive

- A servomotor to "maintain the dimension"

- Safety switches

- Manual

- Control panel

- A 7" touch panel

- A cutting list

- A list containing the following columns: dimension and quantity

- Possibility to connect

- A cutting device, a feeding table, a saw table, shelves under tables