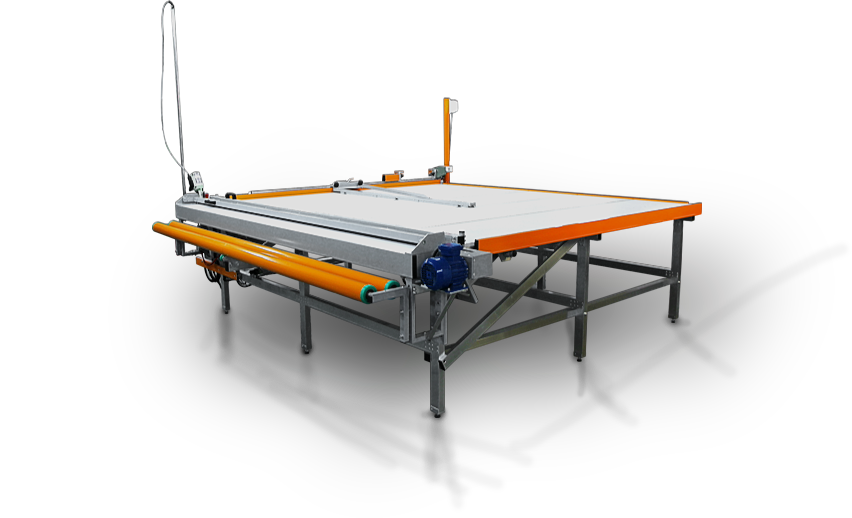

Rollcutter

Complete production in one machine

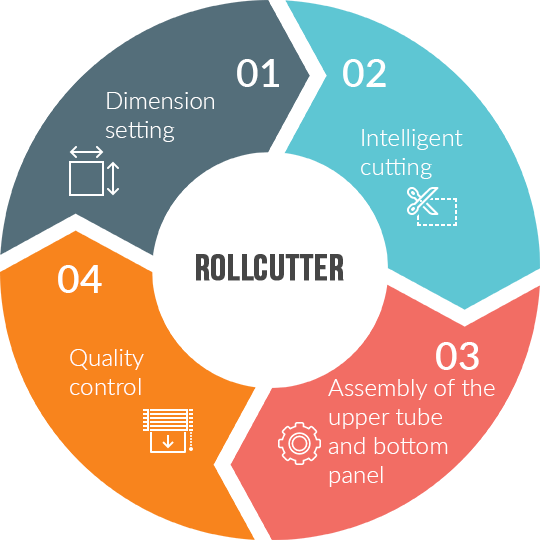

Imagine that you only need one machine to produce an ideal roller blind. A Rollcutter is not just a fabric cutting table but a complete roller blind table that supports every stage of production. From the moment you place the fabric roll on a the table, through the dimension setting stage, cutting, assembling the upper tube and bottom panel all the way through to quality control, all you need is a Rollcutter.

Made to fit

Depending on the level and volume of your production we can prepare a machine that fits your needs. You can choose from five Rollcuter models, adjust the table dimensions, knife type, clamp and other relevant features. We will also advise on the best configuration of auxiliary equipment.

Innovative solutions

Innovations and own solutions form the basis of our projects. The system sending Direct orders from the computer to the machine, fully automated cutting cycle, instant knife change or fabric auto-centering are just some of the innovative solutions that can be found in Draco tables.

240 machines in 40 countries

We started as a roller blind producing company ourselves, and so we know exactly what our customers need. We know the problems that occur during production and we know how to deal with them. Thanks to our knowledge and experience, as well as that shared by the customers from all around the world the Rollcutter makes the production of roller blinds extremely efficient, super easy and pleasant.

Check Rollcutter in action

Additional benefits

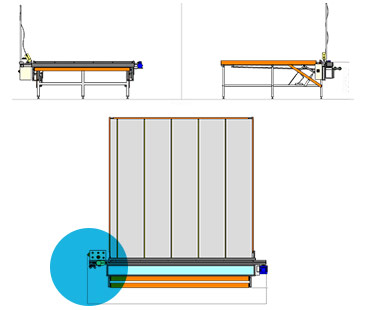

Always straight blinds

The Rollcuter has an aluminium construction that allows for precise adjustment of the right angle (diagonal adjustment), clamp adjustment and table levelling, making roller blinds always straight and equal.

Always safe to work with

Each Rollcuter model is built with usage safety in mind. The machines are equipped in sensors that detect objects under the open clamp, emergency safety switches as well as anti-collision systems for the clamp.

Free training

The Rollcutter stands not only for a roller blind producing machine, but also for a comprehensive knowledge on the complete production process. We will train both you and your employees free of charge in order to use the production potential in an optimal way and minimize the time needed to implement changes.

Immediate support

Should you require assistance we will support you as soon as you contact our consultant.

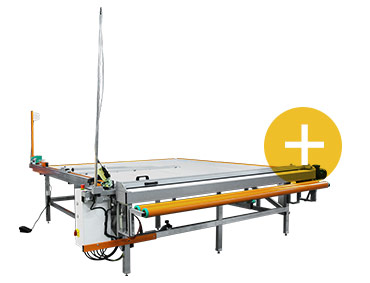

Rollcutter add-ons

By choosing a Rollcuter you receive not only a roller blind production table but also the access to support devices that ideally complement a Rollcutter by extending its capabilities and performance. The currently available add-ons include: Wrapper, Rigid tape feeder, Ruler gauge, Label scanner, Label printer, Control lift.

Models

TYPE-1 |

TYPE-2 |

TYPE-3 |

TYPE-4 |

TYPE-5 |

|---|---|---|---|---|

|

|

|

|

|

|

|

Type-1 is a simple table for one-off production. All activities on this table are performed manually. Roller knife or ultrasound knife can be used for cutting. Read more |

Type-2 is an ideal table for a developing production. It improves productivity with automatic knife feed, furthermore it can optionally be expanded with its production capacity increased. Read more |

Type-3 is the best machine for advanced Production. It incorporates reinforced construction and innovative solutions to improve work comfort. Read more |

Type-4 is designed for large unit and serial production. It enables programming and full automation of the cutting process. Read more |

Type-5 – designed for serial production. The new design enables fastest and fully automatic cutting process. Read more |